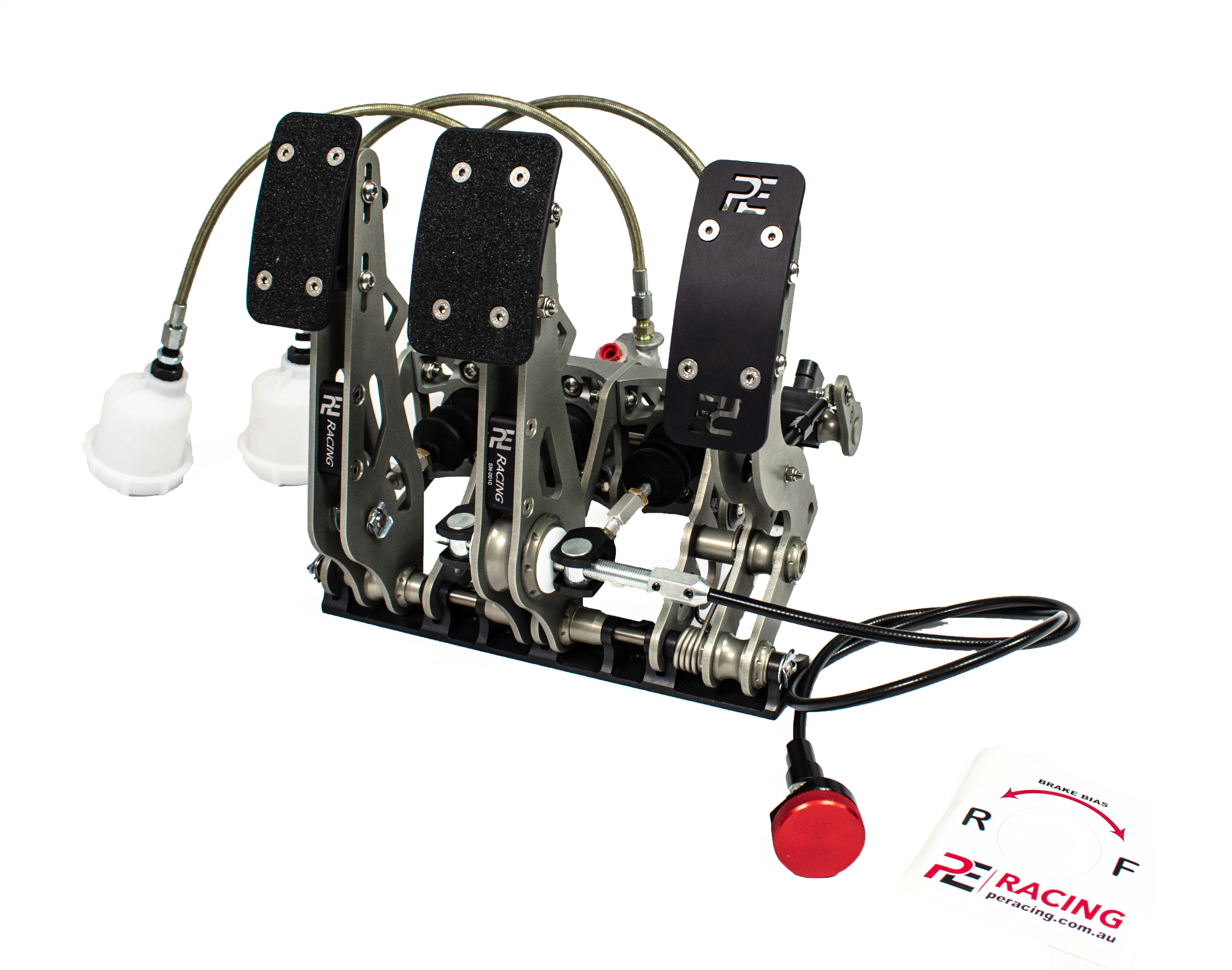

The PE Pedal Box

PE Racing's Floor Mount Pedal Assemblies are one of the lightest in the automotive market.

Built from high-quality aircraft alloy construction with a anodized finish to last in extreme environments.

The PE Pedal Box is a tight and compact design loaded with patent features.

The challenge we set ourselves was to reduce the overall size of the pedal assembly.

We worked on achieving equal fluid pressure & displacement to suit a wide range of motorsport disciplines.

This physical size reduction would aid in further weight reduction, whilst allow fitting in tight spaces, and assist in clearing such items as steering columns.

Collapsible content

Weight

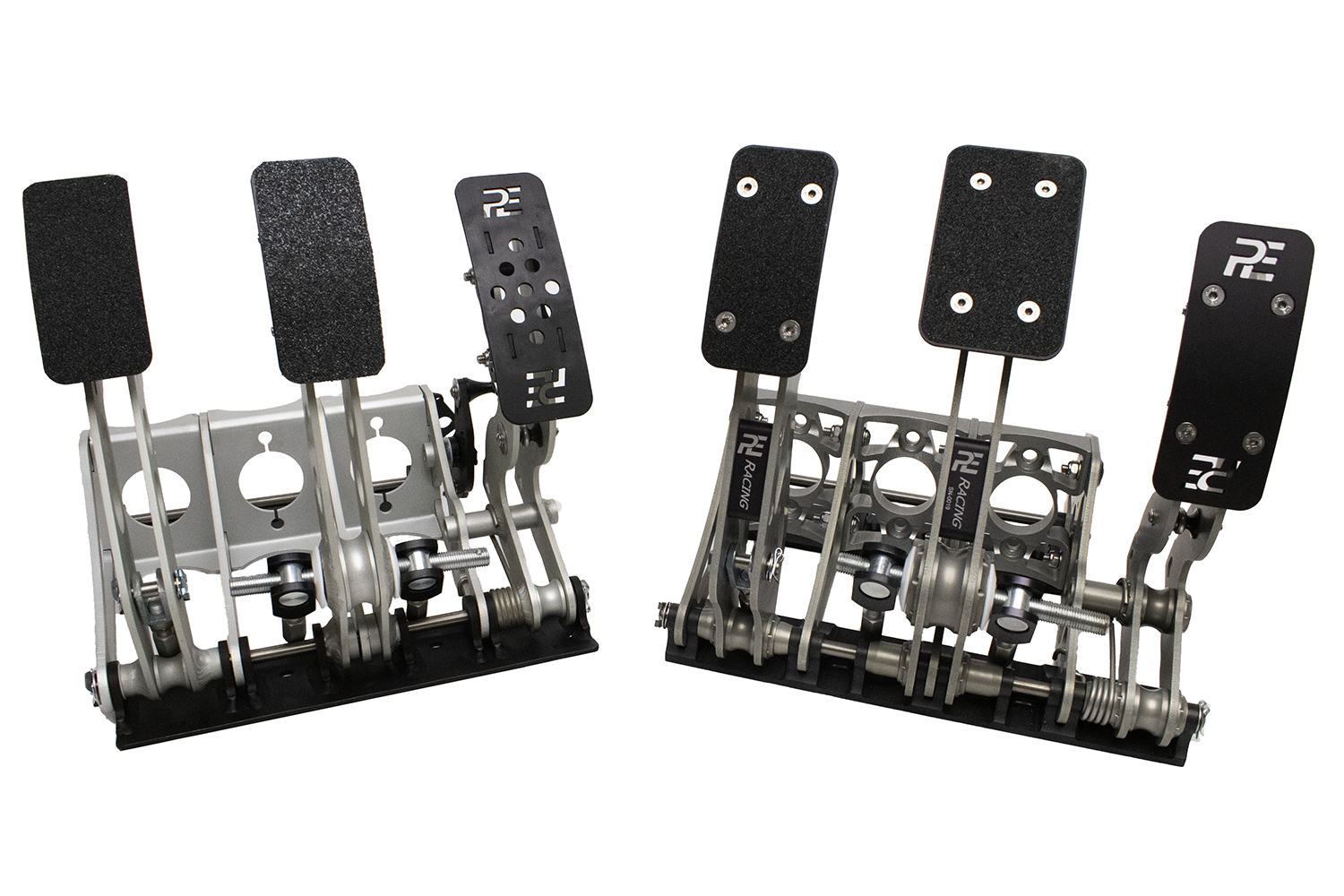

Our Pedal range consists of The Billet and The Fabricated. The difference between the assemblies is the weight and the labour cost for us. The fabricated is hand made and is our lightest pedal box. The Billet is from a Alloy Billet construction.

Net frame weight excludes items such as Master Cylinders, Balance Bar & Throttle Linkage Kits. All sold separately.

BILLET

3 Pedal Manual 2.8 kg

2 Pedal Auto 1.92 kg

FABRICATED

3 Pedal Manual 2 kg

2 Pedal Auto 1.6 kg

Features

Adjustable Lightweight Design

Easy to Install

Adjustable Pedal Pads

Adjustable Pedal Ratio

Throttle Tuning

High Strength Aircraft Alloy Construction

Hard Anodized Finish to withhold corrosive environments

Built in Brake Balance Technology

Adjustable Throttle Linkage Geometry

Stiff Mounting without Reinforcement

Pivot Mounting Feet

Drive By Wire & Cable Throttle option

Adjustable Pedal Faces

The PE Pedal Box range makes adjustments easy, providing you with a Pedal Box to suit your style.

With our patent inbuilt-slots you can adjust the depth, pitch and height angle of the pedal face. This is achieved without removing bolts. Designed to make adjustments easy.

Pedals are designed to be independent of the levers, so adjustments will not effect the mechanics (master cylinder integration or linkages). Featuring adjustable pedal geometry for feel and comfort, once the kit is installed in the desired location at your selected incline angle, the desired pedal face positions can easily be set using the inbuilt adjustment slots. The mechanical advantage can also be increased by raising the pedal faces up or decreased by lowering them down.

Gas Throttle Adjustments

Cable Throttle & Drive By Wire Throttle options.

Features inbuilt spring return and easy adjustment of the linkage geometry.

Once installed, the linkage is easily adjusted to achieve the desired cable stroke. The cable stroke length is achieved via moving the adjustable rod along the slot in the cable linkage.

Very fine settings can be achieved ranging from 30mm to 55mm stroke. The adjustable rod with rod ends allows fine motion ratios to be set to tune your gas throttle progression requirements.

The gas / throttle pedal lever features an inbuilt stop in both directions. A permanent travel stop should be fitted to your vehicle on installation. The desired pedal face position can easily be set using the adjustment slots provided.

Clutch Lever

Manual

The clutch has an inbuilt lever stop high within the frame, minimising the risk of fouling by debris.

The desired stroke or fluid displacement is easily adjusted to suit by selecting the appropriate cylinder bore and setting the push-rod length for adjusting the effective pedal stroke.

The desired pedal face position can easily set using the inbuilt adjustment slots.

Brake Analysis

When you purchase a PE Pedal Box, you get a complementary Brake Analysis Service. The braking ability is highly important to us, as more lap gains are made through braking and cornering.

Achieving ideal brake balance is ultimately obtaining the optimum amount of braking effort which corresponds with the dynamic loads & grip level available.

The Brake Analysis is our in-house dynamic simulation that determines the ideal Pedal Box Configuration & Component Sizing.

Simply download and fill out the form, return it to info@peracing.com.au for your free Brake Analysis.

FAQ

How does a smaller Pedal Ratio work?

The output fluid pressure & fluid displacement is no less than other high quality systems which utilise higher pedal ratios.

How?

The overall mechanical advantage is made up of several factors, mainly being mechanical advantage (the pedal ratio) & hydraulic advantage (the hydraulic ratio).

The pedal ratio, pushrod efficiency, master cylinder travel & master cylinder bore all have an effect on the overall output fluid pressure & fluid displacement.

This design uses a combination of reduced pedal ratio, and increased hydraulic ratio, the combined result is fluid pressure & displacement being equal to other high quality systems, just in a more compact way. We consider this a win/win.

So pedal boxes with higher pedal ratios are not necessarily yielding a higher overall combined mechanical advantage or better efficiency. This is typically due to shorter stroke and larger master cylinder bores being used, ultimately the combined mechanical advantage remains unchanged.

What Master Cylinder should I use?

We use Girling Master Cylinders which have 1.375" of stroke; this is what allows you to operate with a lower pedal ratio for same outputs as higher pedal ratios which shorter stroke masters.

Selecting the bore sizes should not be based on just the dynamic front weight transfer percentage, but rather be sized relative to your callipers piston areas for front and rear.

As an example, if you chose 0.75" Bore Master for front, which calculates to be 4:1 of Calliper Pistons area to Master Cylinder area. Then, rear should be as close as possible to that ratio also.

Generally rear Callipers have smaller piston areasl therefore a smaller master like 0.7" or 0.625" for the rear could ensure that both Masters see similar stroke levels during brake applications. This helps maintain squareness of the balance bar during travel.

Getting this part right is only part of the problem - selecting the correct Rotors & Callipers for example should be done by evaluating your cars dynamic balance & grip.

Take advantage of our Brake Analysis Service.

Why a Floor Mount Pedal Box?

Several reasons. Firstly, it helps lower your cars COG.

Ergonomics, many argue that the low pedal pivot matches foot movement, especially clutch & throttle pedal movements.

Pedal assemblies are mechanical devices which remove the need for a brake booster. Brake boosters provide sluggish feel and the difference between locking a wheel or not could be just a little pedal force difference.

A Pedal box increases the effort required for your brake pedal, but, simultaneously increases feel and accuracy of your control.

Braking is generally considered to be at the greater end of the spectrum when it comes to acceleration G's (in the negative) when compared to acceleration and cornering.

So, increasing your braking ability & control is an effective way to reduce your laptimes.

Which Pedal Box do I chose?

The more compact & lightweight is the Fabricated series at 2kg, so if weight is your priority, this is the one.

The Billet version is less expensive, weighs 2.8 which is still relatively light when compared to other brands.

Both models install in the same way and include the features.

So your choice is only considering weight and cost.

Why does the PE Pedal Box look different to others like Tilton?

Our Patented design came about due to a range of problems experienced over several decades.

Initially the installation of Floor Mounted Pedals often required modifying, removal or addition of materials around floor area (sometimes all).

We initially looked at how we can make a strong and light connection. This lead us to increase the span of the mounting, which is why we have a trussed frame & pivoted mounting feet.

The result, a light install whilst increasing the mounting stiffness.

The other adjustable features of our design are also a result of some other frustrations we experienced. Such as when attempting to tune, it was limited, leading to further modifications & in some cases remanufacturing bits to suit.

Our design is aimed at solving the above issues and making adjustments easy and improving performance.